Upgrade Your Stretch Hood Equipment

From old to new: Discover our cost-efficient retrofit solutions from RHM Packaging. A great choice to upgrade your equipment without breaking the bank.

Short Navigation: Retrofit / Benefits / Control Panel / Programming

What is a Retrofit and why could that be interesting for me?

Retrofit is all about giving your current machine a longer lifetime.

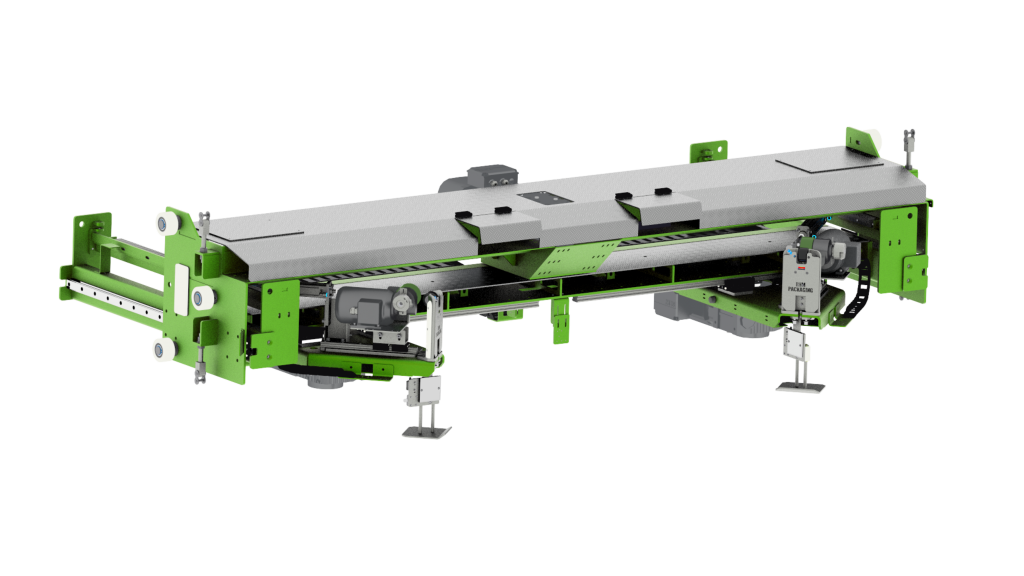

Common to all of our retrofit types is the replacement or significant modification of one or more of the main components in the stretch hood machine. We use the term “retrofit” as it accurately describes the process of making old machines new again, which is a significant part of our business.

We offer different types of retrofits depending on the specific needs and goals of our customers, as well as their budget. Our solutions are tailored to meet the unique needs of each customer, and we work closely with them to ensure that we provide the most effective and cost-efficient solution possible.

There are several reasons why you should do a retrofit with RHM Packaging.

Retrofit your stretch hood machine for stable packaging operations and less film tearing issues.

Are you tired of dealing with film tearing and unstable packaging operations? We know how frustrating it can be to face these issues, which is why our stretch hood machine retrofitting services are designed to provide you with a stable, consistent process that ensures maximum productivity and minimal disruptions.

Enhance the lifespan of your stretch hood machine investment through retrofitting.

Worried about the lifespan of your stretch hood machine investment? We understand how crucial it is for you to get the most out of your machinery, which is why our retrofitting services can help you enhance your machine's durability and prolong its lifespan, reducing the need for costly repairs or replacements.

Retrofit your stretch hood machine for better handling of thinner stretch hoods, reducing material usage while maintaining performance.

Are you struggling with the handling of thinner films and excess material usage? Perhaps even with stretch hoods that include PCR material? Outdated gripper technology can make it challenging to optimize your packaging process for better efficiency and cost savings. We can help you reduce your material consumption and upgrade your machine's technology, providing you with a solution that is both efficient and cost-effective.

Upgrade to a more environmentally friendly solution through retrofitting your hydraulic stretch hood machine to an all-electric model.

Are you looking for a more sustainable and eco-friendly packaging solution that also meets hygiene laws? We know that high energy prices and regulatory requirements can make it difficult to stay competitive in the packaging industry. Our retrofitting services can help you upgrade your hydraulic stretch hood machine to an all-electric version that is energy-efficient and meets all necessary hygiene laws.

Retrofit your stretch hood machine for optimal energy efficiency and cost savings.

Want to optimize your energy consumption and reduce your operating costs? We understand how important it is for you to minimize your energy consumption and reduce your carbon footprint. Our retrofitting services can help you increase the energy efficiency of your stretch hood machine, providing you with a cost-effective and environmentally friendly solution.

If you’re looking for a reliable and cost-effective solution to upgrade your packaging machinery, our Retrofit Service by RHM Packaging is the way to go. Our expert team will help you improve your production efficiency, reduce downtime, and extend the lifespan of your equipment. Contact us today to learn more.

Benefits

Cost savings

A retrofit makes it possible to avoid the expensive investment in a new machine and is often more cost-effective.

Customization

Our Retrofit service allows for customization of the existing equipment to better suit the specific needs of the business.

Less Maintenance

Retrofitting can lower maintenance costs by reducing wear and tear on equipment, resulting in less frequent replacement of spare parts.

Environmental Friendly

A Retrofit of your existing stretch hood machine can help to reduce waste and the carbon footprint associated with buying new equipment.

Success Story

Company

XYZ

Logo Company

Achievement 1

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Achievement 2

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Achievement 3

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

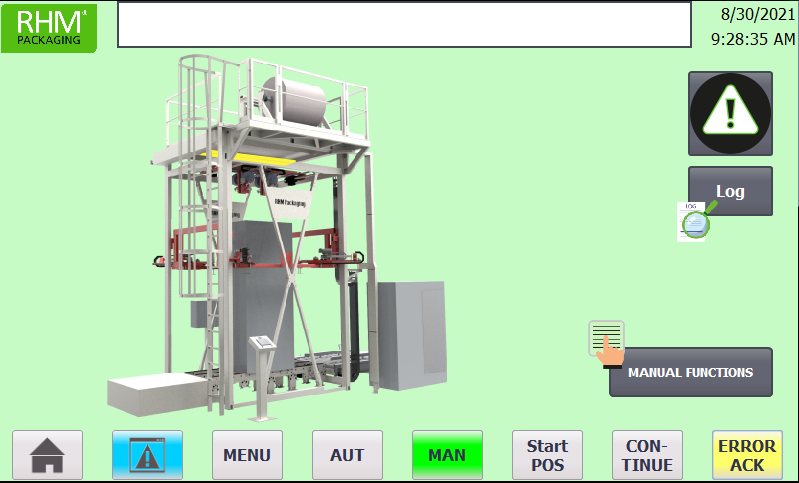

Control Panel

Upgrade your old machinery with the cutting-edge technology of our RHM Panel – the ultimate solution for efficient and reliable performance.

The RHM Panel is a state-of-the-art control panel designed to upgrade old machines. It features advanced technology and a user-friendly interface that makes it easy to monitor and control the machine’s functions. The panel also includes a visual error display that quickly identifies and locates any issues, helping to minimize downtime and improve efficiency. Additionally, the RHM Panel can be integrated with Siemens panels, allowing for seamless integration and improved performance.

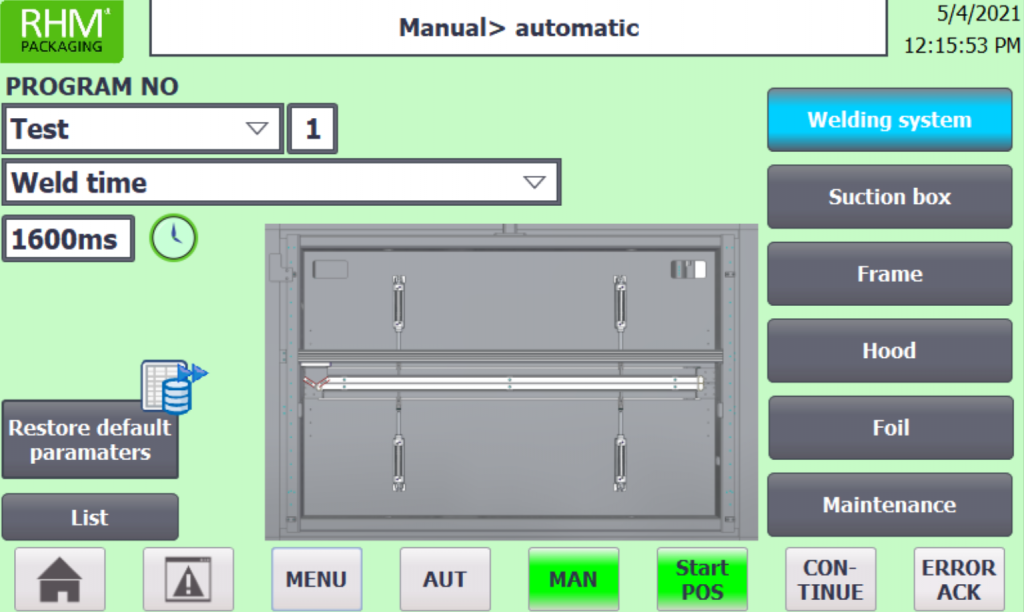

Individual Machine Program with error visualization

Advanced functionality for precise control

Experience the full capabilities of our RHM Panel with a personalized demo. During the demo, our experts will walk you through the features and functions of the panel, answer any questions you may have, and show you how it can be integrated with other equipment.

Programming

Unlock the full potential of your stretch hood machine and optimize your production process with our expert programming services.

Our programming services are designed to help customers optimize the performance of their stretch hood machines and improve the efficiency of their production process. Our team of experts has the knowledge and expertise to customize processes, increase efficiency, and implement control. We can work with you to understand your specific needs and tailor our programming services to meet those requirements. Whether you’re looking to improve the speed and accuracy of your stretch hood machine, or streamline your production process, our programming services can help you achieve your goals. With our help, you can take your stretch hood machine to the next level of performance and efficiency, optimize your production process, and increase your competitiveness.