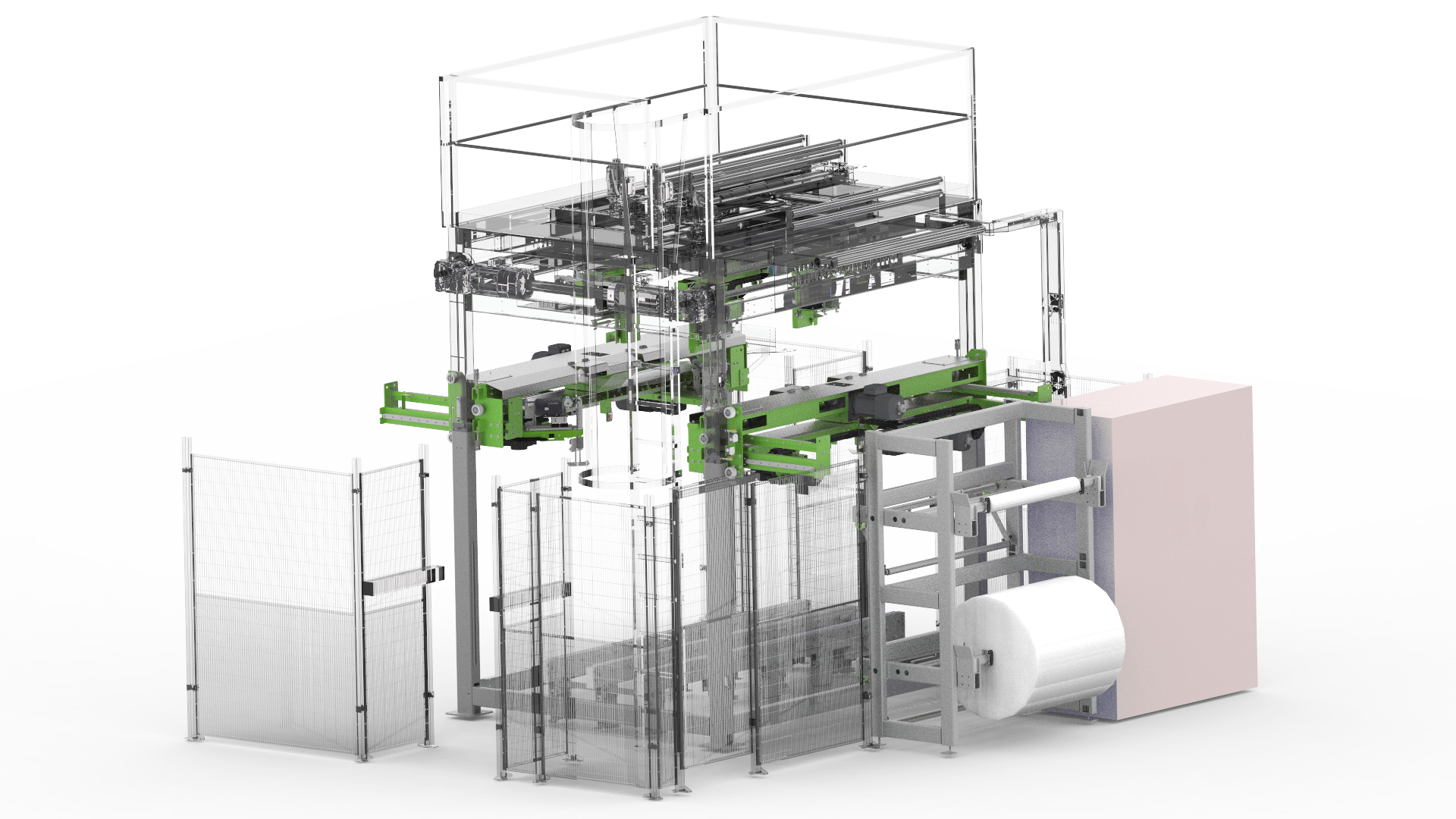

Stretchhood Machine Service customized to your needs.

Keeping your stretch hood machines running at optimal performance. Discover our maintenance and repair services – tailored to your requirements.

Short navigation: Service / Benefits / Customization / Safetyprogram

Maintenance Solutions

Regular stretchhood machine service and maintenance is a valuable key for optimizing your machine’s performance.

- Are you tired of poor after sales service from manufacturers? RHM Packaging offers is your partner for packaging solutions and offers reliable, expert support.

- Are you facing long waiting times for stretchhood machines service? At RHM Packaging, we provide fast responses and efficient solutions to minimize downtimes.

- No budget for cost intensive maintenance? RHM Packaging offers cost-effective service options, tailored to your specific requirements.

- You are in need of a urgent stretchhood machines repair? Call our hotline and we will support you right away.

It is about overview, reliability, cost management and guidance.

When your stretchhood machines are regularly maintained, serviced and inspected, many defects can be prevented. Identifying wear and tear before they significantly impact your production process hleps you avoid unnecessary downtime and saves you follow-up costs.

In addition, regular maintenance helps to increase safety, ensures smooth machine operation and the maximum service life of your stretchhood packaging machine.

Benefits

Improved Reliability

A dedicated maintenance and service offering for stretchhood machines ensures process stability and minimizes downtime. Our proactive approach ensures that your machine operates at optimal performance, reducing the risk of unexpected interruptions in the production process.

Reduce Costs

Have you ever been blown away by the high prices of a maintenance quote? Our efficient processes and a specialization in the stretchhood machine service, allow us to offer more affordable maintenance solutions compared to machine manufacturers.

Spare Parts

Does this particular spare part really need to be replaced every time? We replace the most important spare parts and equip your machine with our durable spare parts - built to last; not to be replaced every few months at great expense.

Fast Response Time and Repairs

Have you ever waited 3 months for a service technician? We have short waiting times for service and maintenance, ensuring minimal waiting time for our clients and being able to react fast. This is especially important for urgent repairs.

Customized Maintenance Plan

Our maintenance plans are tailored to the specific needs of our clients, ensuring optimal performance and cost-effectiveness. You want to have certain parts done by your own technicians? No problem.

Independancy

We provide maintenance and service for all types of packaging machines, not just those from specific manufacturers, providing unbiased and independent service. We know the weak spots of each model and are able to optimize.

We always block sufficient resources to be able to help on site at short notice.

Customization

Business needs are different. The facilities are different.

- The suction boxes, the exterior gripper or the alternative opening system are not working properly? We know the industry issues and weak spots of the different manufacturers such as Lachenmeier, Beumer, MSK or Möllers and are able to provide customized solutions to optimize your machine.

- You want to know how long your machine will last? What do I need to invest to increase the lifetime of my stretchhood machine? After a service, you’ll receive a detailed service report and ideas how the lifetime of your machine could be improved.

- The time slot for a service is really short and you want to reduce the time? We provide packages that allow your technicians to self-service specific areas (e.g. welding wire) that are often time-consuming on their own – this means flexibility: your technicians can do this step when they have time for it and you do not have to pay horrendous prices.

Requirements for corporate packaging are different.

RHM Packaging ApS has prepared a concept within maintenance of facilities, where the individual facility determines which items are included in our service visit.

RHM Packaging ApS adjusts the date and time of service according to the company. We arrive when it fits into your production, at the agreed time.

At the same time as the service visit, our experienced technicians prepare a detailed service report – when they leave your company, you know what they have done, and which upcoming repairs you can expected, if any.

After service, calls, repairs or spare parts replacements, we register the information in our database.

That way, the processing time is minimized if later faults are to be found on the machine – and at the same time there is history on the machine.

In other words, we prepare the service based on the company’s wishes and expectations, instructions for the individual machine and our many years of experience in the field.

RHM Packaging ApS – your service partner for customized and individual stretchhood machine maintenance solutions which fit to your equipment and the company’s needs.

Success Story

Company

XYZ

Logo Company

Achievement 1

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Achievement 2

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Achievement 3

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Brands

Due to our long experience in the industry we are able to offer our stretchhood machine service for various manufacturers’ machines such as Beumer, Möllers, MSK, BTH and Lachenmeier.

One of the main advantages of working with us is our flexibility. We understand that different suppliers have different requirements, and we have the expertise to provide tailored solutions that meet the specific needs of each machine. Whether you need routine maintenance, emergency repairs, or upgrades to your stretchhood equipment, we have the skills and resources to get the job done efficiently and effectively.

Our knowledge of different stretchhood machine manufacturers allows us to provide tailored solutions and optimization suggestions to improve the performance and efficiency of your equipment. By working with us, you can trust that your stretchhood machine is in good hands and operating at its best.

Security Program

Our experience shows that regular stretchhood machine service can prevent unforeseen downtime, while machines that are not well maintained breaks down more often.

Participation in the safety program ensures that the system is kept running with optimal power, as well as with the lowest possible costs for maintenance and repair. The service life of the machines is extended, as the wearing parts are changed regularly and the other parts are readjusted.

The security program is signed for 1 year at a time, and usually includes service once or several times a year, depending on your wishes. We are of course happy to help determine the frequency of service, assessed on the basis of the load on the individual machine.

One of the services that comes with the security program is remote support. An on-site technician is not always necessary, a call to us may be enough and then you are quickly in touch with an expert. In some cases, we can locate the error quickly and remedy the error with targeted solutions, by phone or email. This saves you time and money.

RHM Packaging ApS offers customized and individual service solutions which fit to your equipment and the company’s needs.

Frequently Asked Questions

Are you specialized in Lachenmeier stretch hood machines only?

With more than 30 years of experience in the stretch hood industry, RHM Packaging is able to cover a wide range of stretch hood machine manufacturers. We have already maintained, repaired and serviced machines from Lachenmeier / Signode Denmark (H-Single Flex (HS), CombiFlex (CC), Easy Flex (CA), PowerFlex (HPF-HP01-HP08), MultiFlex (HMF-HM01-HM07), PowerFlex T1 (HT01-HT04), PowerFlex TL (HP12-HP22), MultiFlex X1 (HF01-HF04), Beumer (Beumer Stretch Hood A, Beumer Stretch Hood M, Beumer Stretch Hood S), MSK (Stretch Hooder MSK Tensiontech, Stretch Hooder MSK Wraptech, MSK Hybrid Systems, MSK 371, MSK Covertech), PremierTech Chronos (Stretch Hooder LSH-0100-E, Stretch Hooder LSH-0200-E, Stretch Hooder LSH-0060-E, BTH Rainbow, LSH-1100-N) and Möllers (HSA-Vario, HSA-Vario D). This list covers only a part of the machine types that we have already worked with through the years – let us know if your machine type is not listed here. Chances are high that we know what we must do.

Where can I source spare parts for Lachenmeier stretch hood machines?

Spare parts can be bought directly from Lachenmeier / Signode Denmark or from other companies like RHM Packaging. RHM Packaging has a wide range of spare parts on stock that can be shipped out fast. We have listed a range of spare parts that may be important for you if you need to urgently repair your stretch hood machine: film grippers, stretch hood clamps, cutting blades, sealing elements, drive belts and chains, sensors and photocell, pneumatic components, bearings, rollers, electric and electronic components, rubber components, wheels and castors. These spare parts are on stock and can be used for your Lachenmeier Stretch Hood – we can even prepare a safety-stock for your machine that you can always keep on stock for urgent repairs.

Do I have to buy a new Lachenmeier Power Flex / Multi Flex stretch hood machine?

Most machine manufacturers like Lachenmeier, Beumer or Möllers are of course interested in selling new lines to their customers. However, buying a new stretch hood machine is not always the best choice. A lot of stretch hood machines are not well maintained – that means that the machines are heavily damaged from wear and tear. We are often called from new customers when it is already too late: they have not maintained / serviced their stretch hooder on a regular basis and now their machines are not working properly. This results in line interruptions; productivity is decreasing and the worst thing: the customer eventually needs to invest in a new stretch hood machine. RHM Packaging offers a “Retrofit” service – we will analyze your current Lachenmeier stretch hood and work out a retrofit plan. Our goal is to increase the lifetime of your Lachenmeier stretch hood machine to avoid having to invest in a new packaging line. After our retrofit, customers can use their stretch hood machine many years longer without having to invest. This is a cheap stretch hood machine solution if you are on a budget or want to avoid high capital expenditures (CAPEX). Besides that, RHM offers used / second hand Lachenmeier stretch hood machines. They are available at the fraction of the cost of a new Lachenmeier stretch hood line and are refurbished and upgraded with state-of-the-art stretch hood technology.

Why should I work with RHM Packaging – the machine manufacturer also offers services and maintenance?

Customers that come to us are often not satisfied with the service of their current stretch hood machine manufacturer. These manufacturers are mainly focused on selling new packaging lines and often have a poor After-Sales-Service. Customers sometimes need to wait for several months for a simple service – and when the day has come, an inexperienced technician arrives on site, sprays some WD-40, and leaves after three hours. Spare parts are sometimes not on stock, and the customer must wait for weeks until this critical, electronic part arrives. Stretch hood machines are the bottleneck and end of your end-of-line packaging process – if this machine is not working, you are not able to send out pallets to your customers (earn no money). Many companies have stretch hood machines from several manufacturers – for example one Lachenmeier line and another Möllers line. We can maintain and service both machines and you can save money and time, because you do not have to call two companies.

Why is my stretch hood always tearing, pulling holes and causing errors?

Most machine manufacturers are not really experienced with stretch hood film. They do not want to be involved in the stretch hood film / hooder film topic and when problems arise, everyone starts finger pointing to the other party (machine manufacturer vs. stretch hood film manufacturer). The result: you and your operators must improvise and find a solution – this causes a lot of stress, trouble and in the end, the solution is also not always perfect. But at least the stretch hood line is running, and no operators must climb into the machine. Something that is often forgotten: this stretch hood line may waste a lot of money and energy. Most stretch hoods currently can be downsized, formats can be adjusted (they have been suggested by the machine manufacturer several years ago without being challenged once since then) and the technology (for example hydraulics) could be upgraded as well. Having an expert with over 30 years of experience in stretch hood machinery could be a great idea and solve most of your problems.