Refurbished Stretch Hood Machines for Sale

Get the latest technology at a fraction of the cost with our used machines, all backed by our guarantee.

Short Navigation: Used Machines / Machines on Stock / Process / Benefits

Used Machines

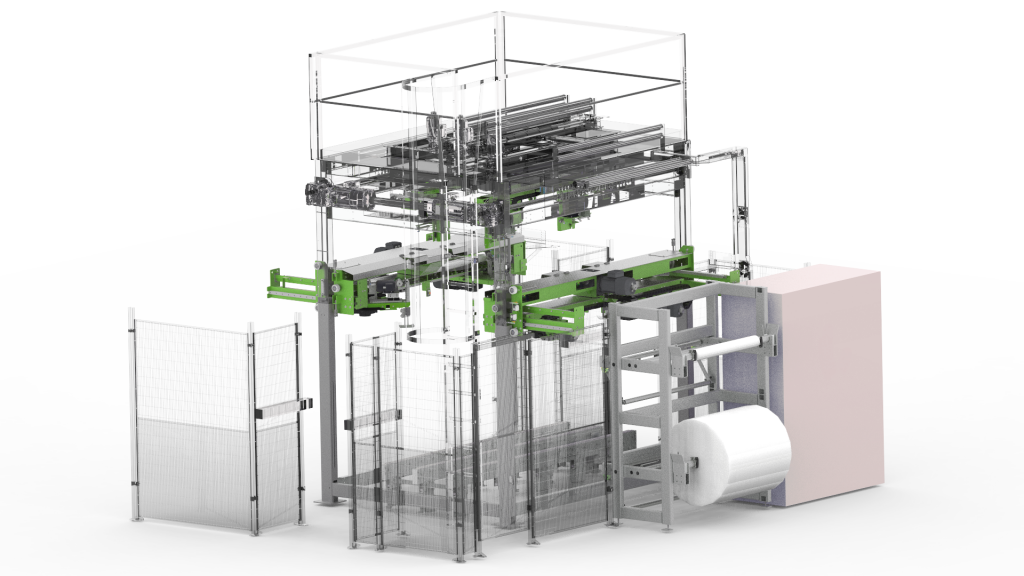

A fully refurbished packaging machine unites environmental, economical and performance advantages for your business.

- You don’t need to invest high sums in a new stretch hood machine. RHM Packaging offers refurbished machines that are upgraded to state-of-the-art technology.

- We buy and dismount used machines on site, upgrade them in our production hall in Denmark and then integrate them into your packaging line.

- We buy used machines from brands like Lachenmeier, Beumer, MSK or Möllers and upgrade them individually.

Buying a used machine does not mean, that you get a lower quality. Quite the opposite with us! We refurbish and fully upgrade those machines to the latest technology for you.

An investment in a used machine can save you a lot of money without dispensing on performance. Additionally it is a sustainable way to give a used machine a second life with an up-to-date technique.

Save money and protect the environment with on top-of-the-line equipment by using one of our fully-upgraded used machines.

Current Stock

Lachenmeier

Power Flex

- Year: 2008

- Pallets per Hour: 60+

- Frame Size: 3600 x 2500 mm

- Max. Load Height: 2200 mm

- Max. Load LxW: 1200 x 1000 mm

- Stretch Hood Film: 1

- Refurbished

- Very well-maintained

- Long Lasting Spare Parts by RHM

Lachenmeier

H-Single

- Year: 2003

- Pallets per Hour: 50+

- Frame Size: 3000 x 2400 mm

- Max. Load Height: 1000 mm*

- Max. Load LxW: 1200 x 800 mm

- Stretch Hood Film: 1

- Refurbished

- Very well-maintained

- Long Lasting Spare Parts by RHM

Lachenmeier

Power Flex

- Year: 2004

- Pallets per Hour: 60+

- Frame Size: 3600 x 2500 mm

- Max. Load Height: 2300 mm

- Max. Load LxW: 1300 x 1100 mm

- Stretch Hood Film: 1

- Refurbished

- New RHM20 Grippers

- Long Lasting Spare Parts by RHM

Lachenmeier

HS-3

- Year: 2001

- Pallets per Hour: 60+

- Frame Size: 2400 x 2200 mm

- Max. Load Height: 1300 mm

- Max. Load LxW: 800 x 600 mm

- Stretch Hood Film: 1

- Refurbished

- New Special Product Sled

- Long Lasting Spare Parts by RHM

Lachenmeier

Multi Flex

- Year: 2008

- Pallets per Hour: 60+

- Frame Size: 3300 x 2500 mm

- Max. Load Height: 2400 mm

- Max. Load LxW: 1250 x 1150 mm

- Stretch Hood Film: 2

- Refurbished

- New RHM Display Panel

- New RHM20 Grippers

The Used Machines Process

What do I get if I buy a used stretch hood machine from RHM Packaging?

Get the latest technology at a fair price with RHM Packaging’s “Used Machines Process” for your stretch hood machine. Upgrade your old equipment to a fully functional, state-of-the-art machine with new grippers / arms, all at a fraction of the cost of a new machine. Our team of experts removes, restores, tests, and integrates the latest advancements to ensure a seamless transition. Choose a sustainable solution that benefits both your business and the environment with RHM Packaging’s “Used Machines Process”.

Our refurbished stretch hood machines, sourced from top manufacturers like Lachenmeier, Beumer, MSK, BTH, and Möllers, are a specialty at our company. Our expert engineers have developed detailed plans to restore these machines to their original high-performance state. Additionally, we can transform your outdated shrink hood machine into a high-tech stretch hood machine.

1. Machine Removal

We carefully remove the used machines from your facility and transport them to our workshop for upgrading.

2. Restauration

Once we have the machine in our production hall, it gets completely overhauled and brought up to the latest standards.

3. Testing and Approval

The machines are then rigorously tested to ensure they meet our high standards of performance and efficiency.

4. Machine integration

We will then dismantle the machine again and integrate it into your packaging line , ensuring a seamless transition to your new equipment.

5. After Sales Service

Our commitment to customer satisfaction doesn't end with the installation of the upgraded machines.

Upgrade your used machines with RHM Packaging’s “Used Machines Process” and experience the benefits of state-of-the-art technology at an affordable price. Contact us today to get started.

Benefits

Environmental Friendly

Buying used machines instead of new ones helps to reduce the carbon footprint.

Customization

Our used machines can be adjusted to different production requirements and can be integrated into existing production lines.

Energy Efficient

Our used machines have been retrofitted for energy efficiency, resulting in cost savings for our clients.

Guarantee

We stand behind the quality of our used machines with a guarantee. Up to three years.

Success Story

Company

XYZ

Logo Company

Achievement 1

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Achievement 2

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Achievement 3

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

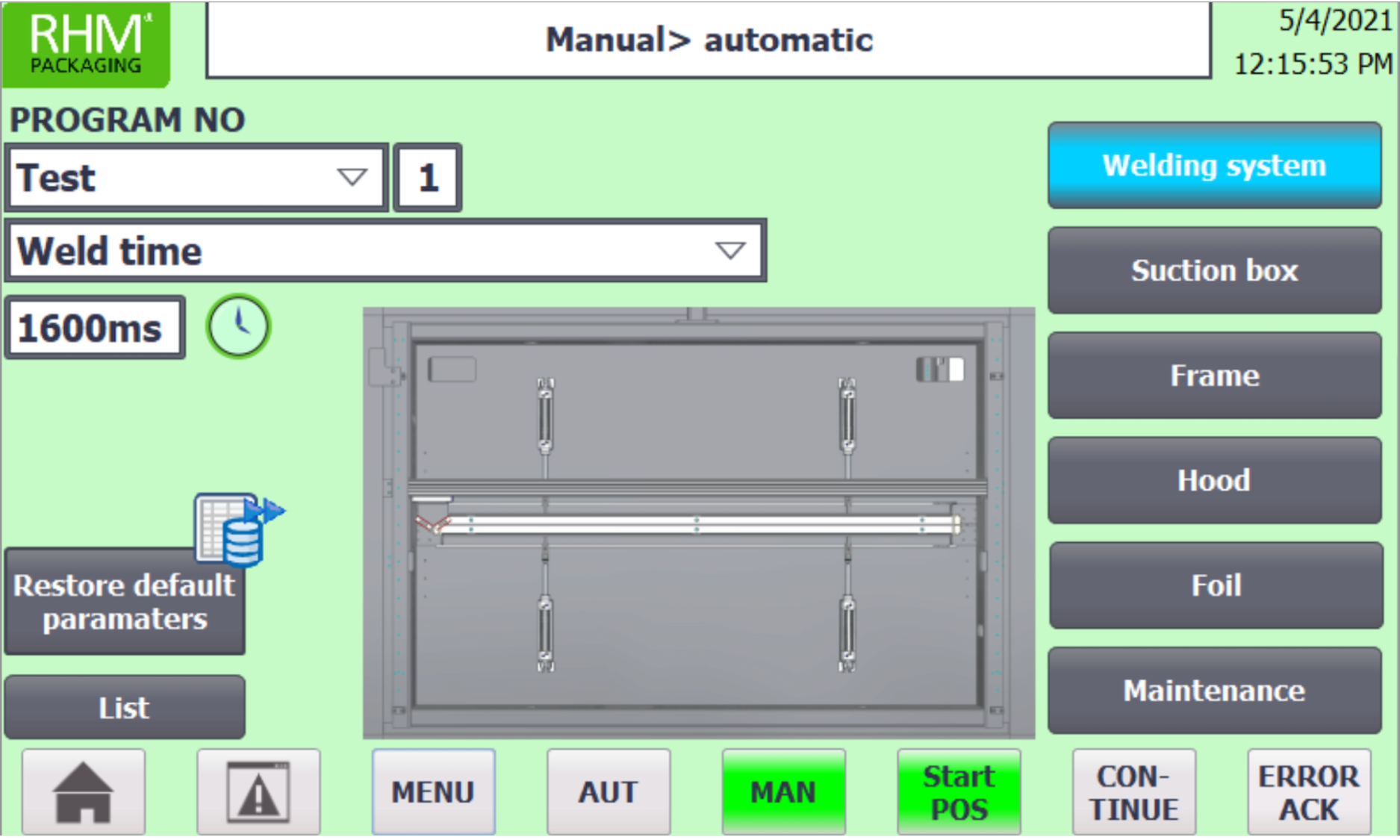

Upgraded to the Latest Technology

Upgrade your old machinery with the cutting-edge technology of our RHM Panel – the ultimate solution for efficient and reliable performance.

At our company, we specialize in offering refurbished used machines that are equipped with cutting-edge technology to improve their efficiency and reliability. We understand that customers may have different budget requirements, and we work to provide solutions that are tailored to their needs.

One of the solutions we offer is our RHM Panel, which is a state-of-the-art control panel designed to upgrade old machines. With advanced technology and a user-friendly interface, the RHM Panel makes it easy to monitor and control the machine’s functions. The panel also includes a visual error display that helps to identify and locate issues, minimizing downtime and improving efficiency. The RHM Panel can be seamlessly integrated with Siemens panels, further enhancing its performance.

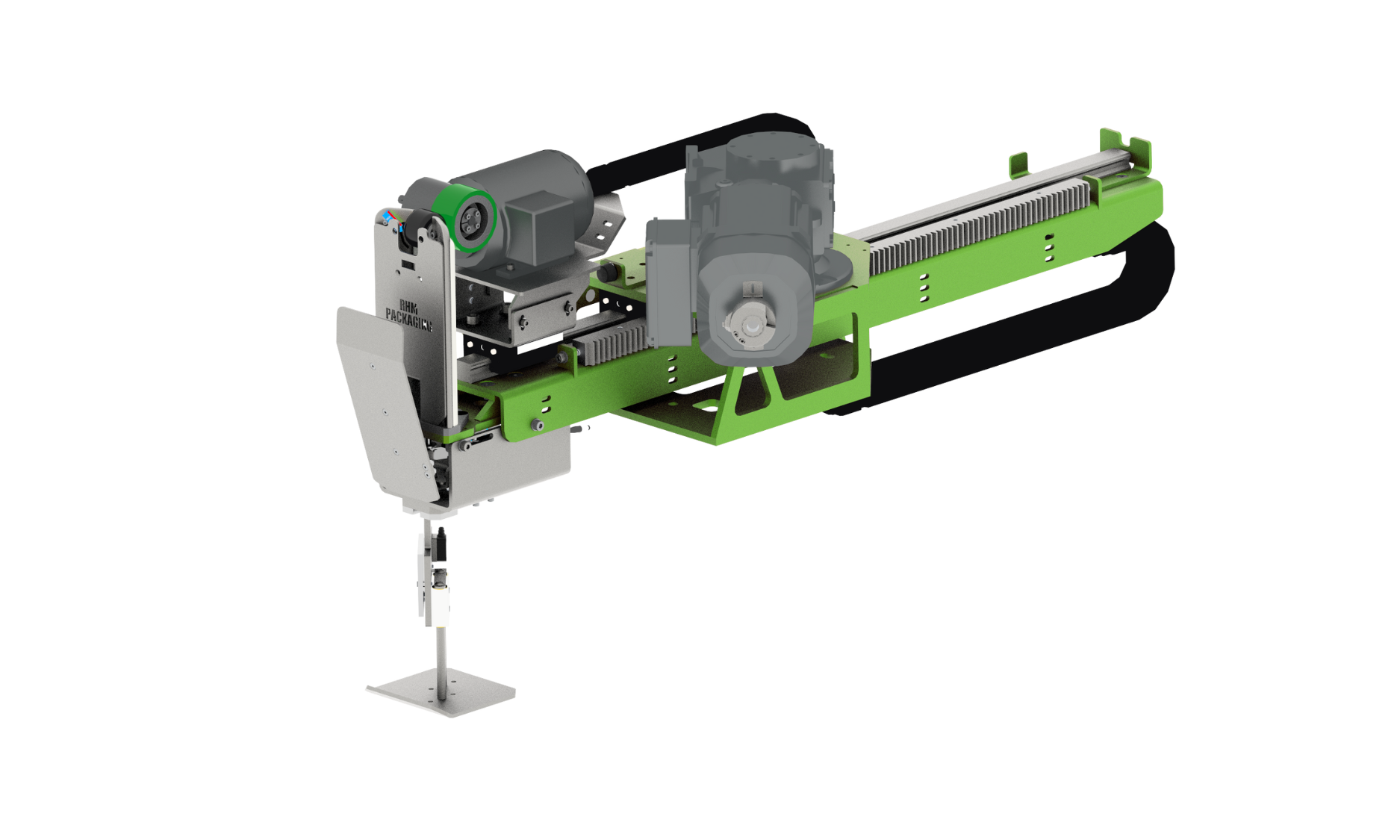

We also offer RHM20 Grippers, which were developed to address problems experienced by our customers with the original grippers from various manufacturers. Our grippers are made with a wear-resistant material that offers a long lifespan, and Teflon bars are used to reduce friction and avoid overstressing the film when stretched. Additionally, a film detection sensor on the gripper simplifies its adjustment and detects any tearing in the film. The gripper wheel made of POM, guided by two bearings, is positioned high up on the gripper, which prevents any issues with unrolling the film.

Our intuitive smart RHM panel enables easy operation

Advanced functionality FOR THE PERFECT FILM PROCESSING

Budget-Friendly Solutions: We understand that each customer may have different budget requirements. Our team works with customers to offer solutions that fit their budget while still providing significant improvements to their machinery’s efficiency and reliability. With our expertise and experience in the industry, we can recommend solutions that are both cost-effective and efficient, helping our customers get the most out of their refurbished machines.