Innovative Stretch Hood Solutions

Discover the benefits of RHM Packaging’s comprehensive stretch hood solutions.

What Makes Us Unique

Customer Orientation

We provide a wide range of stretch hood services, all designed to meet the specific needs of our customers, with a customer-focused approach that guarantees maximum efficiency and satisfaction.

Innovation & Creativity

We are committed to pushing the boundaries of what is possible in our industry through our constant focus on innovation and creativity. Our team is dedicated to developing new and unique solutions to meet the evolving needs of our customers.

Reliability

We understand the importance of a trouble-free packaging process with your stretch hood and strive to provide reliable services. We achieve this by utilizing high-quality parts and performing regular maintenance to minimize downtime. Our focus on reliability ensures that our customers receive the highest level of productivity, effectiveness, and contentment.

Efficiency

At our stretch hood services, we focus on utilizing advanced technology and processes to enhance productivity, lower costs, and decrease energy consumption. Our aim is to reduce downtime and optimize run-through time, allowing our customers to focus on their core business while we take care of the packaging process.

Machines

Get the latest technology at a fraction of the cost with our used machines, all backed by our guarantee.

Service

Keeping your stretch hood machines running at peak performance with our high-quality spare parts and maintenance.

Stretch Hood

End the fingerpointing between multiple suppliers by obtaining both stretch hood and machine from a single, dependable source.

Years of Experience

For over 30 years, René Hansen and the team at RHM Packaging have been at the forefront of the stretch hood industry. Our full-service offering includes maintenance, repair, spare parts, stretch hood film and even used machines, ensuring that our clients receive the best possible solution for their needs.

Innovation

Sustainability is now.

The future starts with today’s decisions.

“Does your packaging machine really need to be replaced with a new one?”

“Are stretch hoods made from recycled materials necessary?”

It is often worth taking a closer look – ecologically but also economically.

Machines that we handle

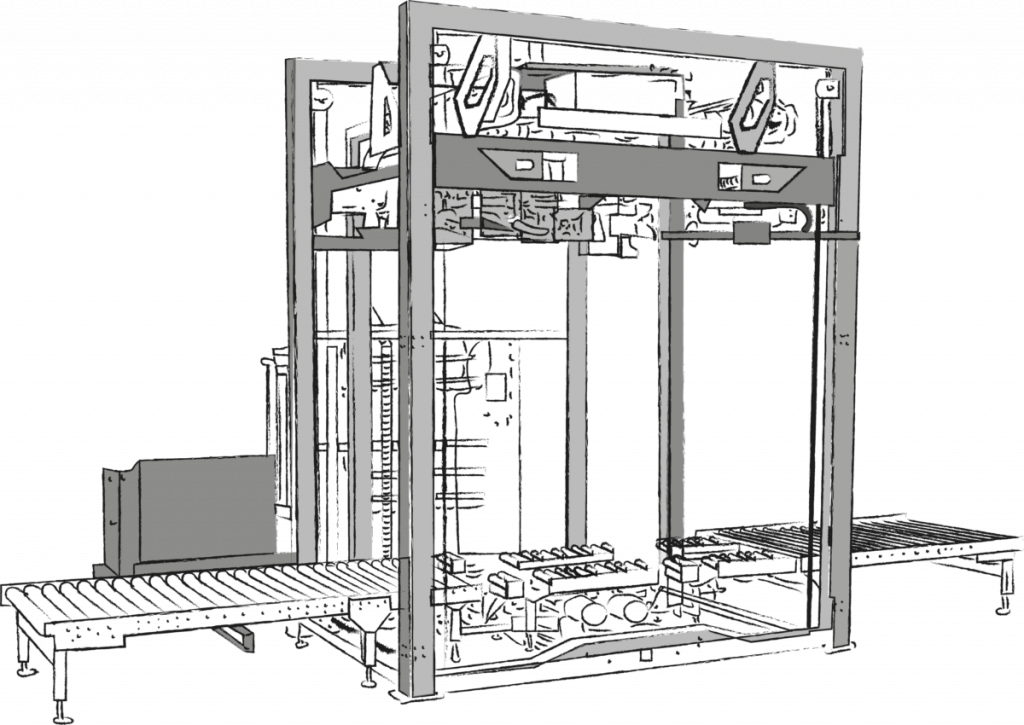

Stretch Hood Machine

Stretch hood is a cost-effective and energy-efficient packaging solution for securing goods on pallets. Unlike shrink wrap, stretch hood requires no heat during application and can be used with a mechanical stretch hood machine. With a often thinner foil and lower raw material consumption, stretch hood provides a sustainable alternative to traditional packaging methods.

RHM Packaging is a leading provider of stretch hood machines, packaging film, and services. We are committed to helping our customers stay ahead of the curve in the packaging industry and are well-equipped to support those looking to make the transition away from shrink wrap to stretch hood.

Shrink Hood Machine

Shrink wrapping is a commonly used method for packaging and securing goods on pallets. The process involves inflating a shrinkable film over the items and then heating it up to shrink the film tightly around the goods. This provides excellent load stability and protection during transportation. However, shrink wrapping has several downsides, such as the high energy consumption required to heat the film, the potential for damage to the goods during the heating process, and the significant amount of waste generated by discarded shrink film.

How to switch from shrink hood to strech hood?

At RHM Packaging, we understand the challenges and limitations of shrink wrapping. That’s why we offer a cost-effective and sustainable alternative to traditional shrink wrapping – stretch hood machines. Additionally, we specialize in buying and refurbishing used shrink hood machines and upgrading them to state-of-the-art stretch hood technology, allowing customers to make the transition to stretch hood machines with ease. We can support you during this step in order to make it as smooth as possible.

Customers that rely on us

News

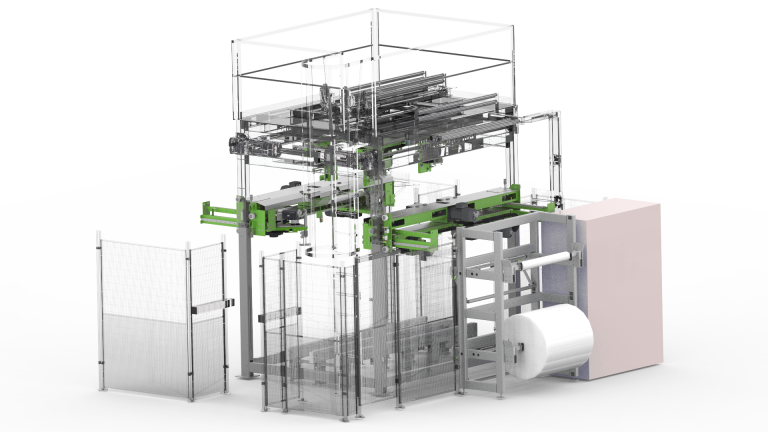

Watch how it works

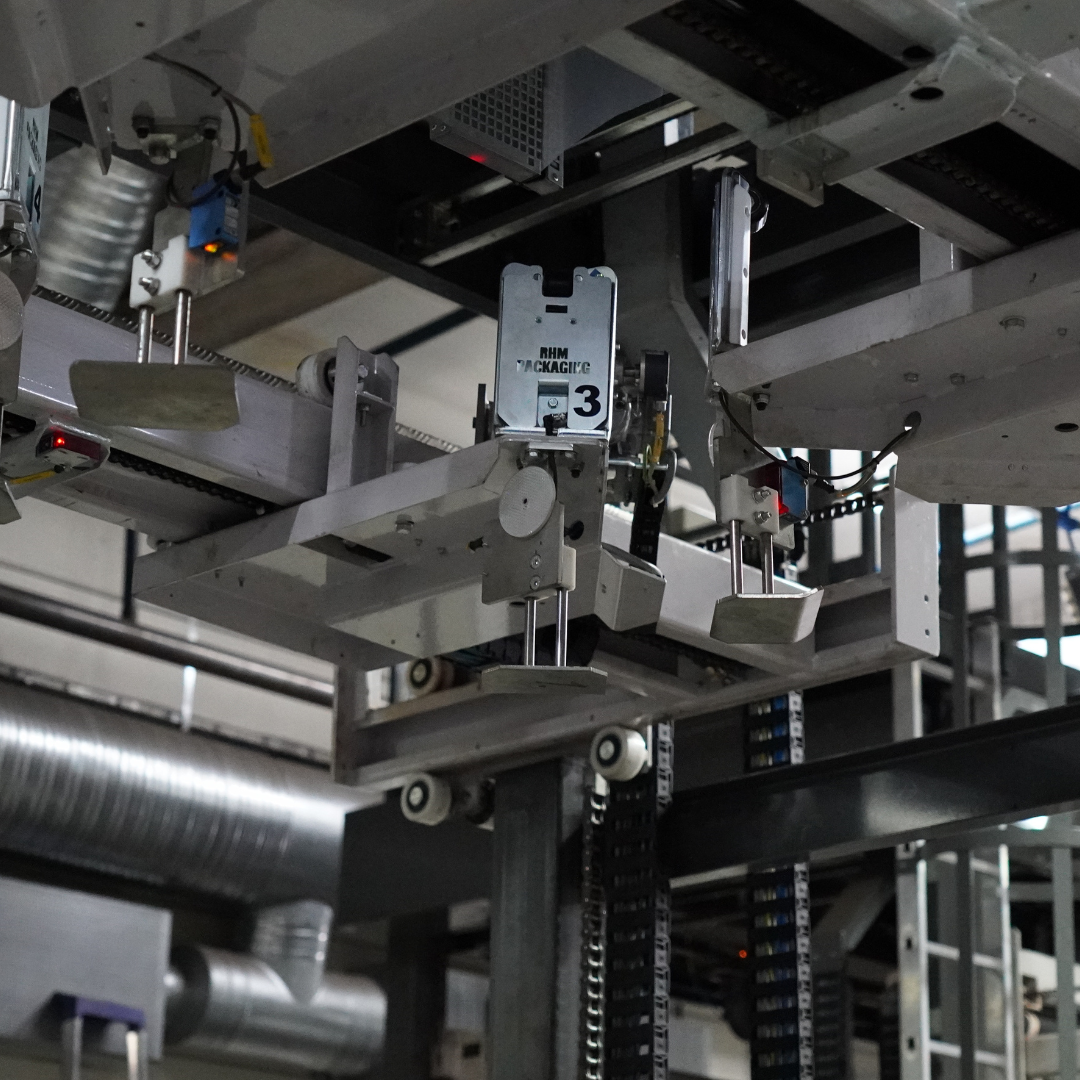

A stretch hood machine secures palletised loads by applying an elastic film hood over the entire pallet, ensuring stability and protection during transport and storage.

The process works as follows:

- Film feed & opening: The film is fed upward and opened by suction boxes to form the hood.

- Stretching: Stretch arms extend the film evenly on all four sides.

- Hood application: Grippers pull the stretched film smoothly over the pallet, creating a tight and secure load.

The result is a reliable, fully automated packaging process with consistent load stability and protection. At RHM Packaging, we design, service, and optimise stretch hood systems to ensure efficiency, reliability, and long-term performance.